This article is an excerpt from my recently published book The Carbon Farming Solution: A Global Toolkit of Perennial Crops and Regenerative Agriculture Practices, and was part of a series promoting my kickstarter campaign to raise funds with which I completed the book.

Though we rarely think of it, starch is the number two most used carbohydrate in industry, coming just after cellulose which is used in great quantities in papermaking. Unlike many industrial crop categories, there is no “synthetic starch” being made from fossil fuels. The situation, however, is not much better. All, or virtually all industrial starch comes from annual food crops, grown in conventional tillage systems. In fact, 17% of European grain goes to papermaking every year. So first we’re using annuals where perennials might fill the gap, and second we’re using food to make cardboard and drywall. This seems like a waste of food, and if we want to minimize the use of annuals we need to find another strategy. Efforts are also underway to genetically modify plants to produce particular starches useful to industry. Given the wide range of starch types available in nature, and the ingenuity of chemists, I think this is unnecessary and somewhat alarming.

Materials from Starch

Starches are important constituents of paper and cardboard, binding to cellulose fibers to strengthen the final product. They are also used for their binding properties in textiles. Surprisingly, starches are also used in numerous construction products for their binding and thickening properties, such plasterboard, glues, joint compounds, paints, foams, and ceiling coatings. Starches are important components of bioplastics. One example already in commercial production is starch-based packing foam, which replaces petroleum-based Styrofoam packing peanuts.

Bioplastics are defined as “biodegradable plastics whose components are derived entirely or almost entirely from renewable raw materials.” (Stevens, 104) Plastics are a clear case where replacing fossil fuels means more than looking at energy. You can’t make plastic from solar or wind. Four to five percent of all oil and gas that are refined go to make plastics. Worldwide, 100,000,000 tons of plastic are produced every year, almost all made from fossil fuels. The great majority of these are not biodegradable, causing an incredible pollution problem. Many toxic processes are used to make them, and some partially degrade into serious contaminants as well. It turns out that people have been making plastics from natural materials since the mid-1800s. In fact, Henry Ford debuted a car mostly made from soy–based plastics in 1941, though World War II ended up distracting the world from this achievement (Stevens, 115). Scientists are hard at work developing bio–based, compostable plastics which are made from renewable feedstocks and can break back down into organic matter. What’s missing is an emphasis on perennial, non-destructively harvested feedstocks, especially non-food crops. Bioplastics can be made from cellulose, starch, oils, resins, and other plant–and animal–based materials. Interestingly bioplastics are not necessarily biodegradable, nor is their production necessarily non-toxic. Scientists are working to emphasize non-toxic production and full compostability and have developed many products that meet those needs. Some compostable bioplastics are already in the marketplace. Some are simple and based on starch (at this point mostly GMO corn, obviously not my favorite). These include the extruded foam packing peanuts you may have received in the mail as well as agricultural plastics, trash bags, plasticware, and diapers. Some longer–lived bioplastics can be created by fermenting starches and other biomaterials. These include polyhydroxyvalerate (PHBV), a rather promising new material. Several other bioplastics are getting more attention including some based on polymerized resins like polylactic acid-based (PLA) plastics .

When I think of plastic-making I imagine giant industrial facilities. I was surprised and pleased when I read E. S. Stevens’ Green Plastics, which gives recipes to make bioplastics in your kitchen with simple materials like cornstarch, glycerin, and gelatin.

What does bio–based, carbon–sequestering, decentralized, low–tech, socially–just plastic production look like? I’ve become very hopeful about the potential for small–scale, regional bioplastic facilities around the world, providing necessities like irrigation pipes and more from local, perennial feedstocks.

Chemicals from Starch

Starches have binding and stabilizing properties that make them useful in numerous chemical products. For example, they are used in pharmaceuticals, agrochemicals, and other products as binders, coaters, flocculants, coagulants, finishing agents and stabilizers. Starches are also used as fermentation substrates for the production of various chemicals. Products include pharmaceuticals, glucose, biopolymers, and “platform chemicals” like lactic acid which are used as building blocks in the chemicals industry.

Energy from Starch

Starches are used to produce ethanol, though sugar is more commonly used.

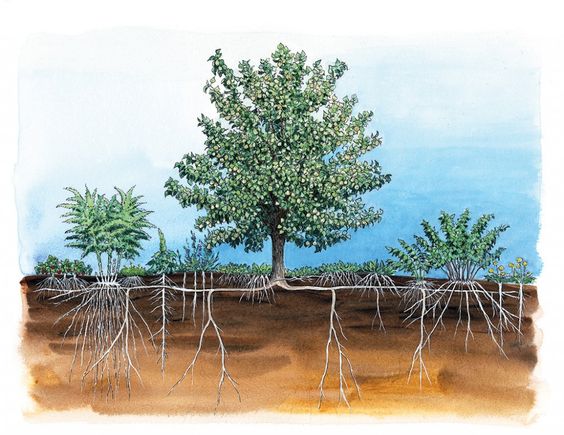

PERENNIAL CROP TYPES

Non-destructively harvested perennial starches include nuts, grains, woody pods, starchy fruits, starchy resprouting trunks, and aerial tubers. Certainly edible perennial starch crops can be used for ethanol production and industrial starch uses, though food should come first. More interestingly, the need for non-destructively harvested perennial starch crops for industrial purposes offers a somewhat novel and intriguing use for a class of plants that has, until now, been largely neglected: plants producing poisonous or non-edible carbohydrates, such as inedible nuts and starchy fruits.

These crops, integrated in diverse perennial agroecosystems, can provide starches for various industrial uses. This is a great use for the inedible forms of air potato, which are already so abundant in areas they have naturalized, and are native to almost half the world’s tropics. This might also provide a use for toxic nuts that have traditionally required extensive processing before eating, like horse chestnuts, cycad nuts, and Moreton Bay chestnuts. It would of course be important to distinguish between edible and non-edible crops in the stage of harvesting and processing. Breeding oaks for industrial starch would simplify the domestication process – annual bearing would still be a goal, but there would be no need to breed out the tannins. In fact, tannins themselves are a useful industrial product that could be removed in the processing plant.

Another reason to cultivate inedible carbohydrates is the principle of agricultural biodiversity. Why not just use perennial edible carbohydrates? Because if we mix up plant families and utilize different crops, we diversify our crop mix and lessen pest pressure on edible starch producing perennial crops. Greater diversity also enables greater flexibility in polyculture design and management.

Interestingly this is a difficult category to collect data on, as it has not been important until recently. Each region could assess its local native species for potential candidates.

Inedible or poisonous, non-destructively harvested starch crops of the world. Note that this is a very preliminary table and many more species are present throughout the globe.

| Latin Name | Common Name | Region of Origin | Starch Type |

| Aesculus spp. | Horse chestnut, buckeye | Americas, Eurasia | Nuts |

| Castanospermum australe | Moreton Bay chestnut | Australia | Nuts |

| Corynocarpus spp. | Karaka | New Zealand | Nuts |

| Cycas spp. | Cycad | Africa, Asia | Nuts |

| Dioon spp. | Cycad | Mesoamerica | Nuts |

| Dioscorea bulbifera | Air Potato (toxic forms) | Africa, Asia, Australia | Aerial Tubers |

| Encephalartos spp. | Cycad | Africa | Nuts |

| Maclura pomifera | Osage Orange | North America | Starchy Fruit |

| Macrozamia spp. | Cycad | Australia | Nuts |

| Microcycas calocoma | Cycad | Caribbean | Nuts |

| Zamia spp. | Cycad | Americas | Nut |

Each region should develop a list of their native and naturalized resources before importing toxic plants from elsewhere. Source: Mind-Altering and Poisonous Plants of the World, Ben-Eric Van Wyk.

CROP PROFILES

Osage orange (Maclura pomifera). Osage orange is a cold-hardy member of the mulberry family, and like its tropical relatives breadfruit and jakfruit, produces a large green starchy fruit the size of a grapefruit. That is where the resemblance ends, however, as Osage orange is inedible and perhaps somewhat toxic (though the small seeds are apparently edible). Native to a small area of Texas and adjacent states, Osage orange turns out to be widely adapted to warm and cold temperate climates, from semi-arid to quite humid. I grew up with Osage oranges in the front yard and I can attest to the high yields. Female trees bear annually and some bear heavily. Yields as high as 450 kg/tree in undomesticated trees have been reported. Extrapolated to 100 trees per hectare, this gives 45 tons per hectare. Keep in mind though that the fruits are 80% water, yielding thus something less than 9 tons of starch per hectare (comparing favorably to corn though with more processing). These rather impressive yields of starch bode well for use in industrial starch uses like papermaking and bioplastics. The fruit also contains hydrocarbon triterpenes, a potentially interesting petroleum replacement. The fruits also contain proteolytic enzymes used in cheesemaking and other applications. Osage orange coppices strongly and is one of the best firewoods in the United States. It is reputed to be the finest wood for archery bows. Vast hedgerows of osage orange were planted throughout the eastern and central US as thorny living fences before the development of barbed wire. This tree certainly has its drawbacks. The inedible fruits are currently regarded as a nuisance. Their stickiness occasionally causes choking death in cattle that try to eat them (though some horses enjoy them). The vicious thorns are problematic in many contexts. Finally, osage orange has naturalized rather aggressively wherever it has been planted. However, if we as a society desire industrial starch and it’s benefits, Osage orange offers many soil-building and carbon-sequestering benefits over production of annual grains or tubers. To my knowledge no one has ever selected Osage orange varieties for superior fruit production. With the large feral populations available, great candidates surely are already out there. The plants are dioecious, with male and female flowers on separate plants, though some female plants apparently set seedless fruit without a male present. Production of female-only clones may offer a strategy for cultivation without the potential for naturalizing outside its current range. However, some females apparently set viable apomictic (cloned) seed without males present. Those of us in cold climates can also dream of a wide cross between Osage orange and jakfruit or breadfruit, aiming for the cold-hardy edible starchy fruit of our dreams. It has reportedly been crossed with the related edible Cudrania tricuspidata, though some question the validity of the cross and the fruits from that hybrid were certainly not edible when I tried them (in fact they looked and tasted a lot like regular Osage orange fruit). The 16% protein dry weight of osage orange fruit, as well as the small but edible seeds, would be a great addition to a future cold-climate perennial staple crops.

Cycads (Division Cycadophyta). Though these ancient plants superficially resemble palms, they are part of a lineage that arose long before the origin of flowering plants. They are adapted throughout the tropics and subtropics, with species for sun and shade, desert, swamp, and rainforest. Most or all fix low amounts of nitrogen through a partnership with blue-green algae in the roots. Cycad “nuts” can be produced in fairly large amounts and are high in starch. Most are very toxic, though some species are processed for food during famines. This slow-growing but long-lived group of plants are utterly unrelated to any commercial crops, offering a change to produce industrial starch while taking a complete break from traditional food crop families. Genera to investigate include Cycas, Dioon, Encephelartos, Macrozamia, Microcycas, and Zamia. There are native species throughout the tropics.

Horse chestnuts and buckeyes (Aesculus spp.). This toxic, starchy nut genus in the soapnut family has representatives all over the cold temperate parts of the world, as well as some tropical highland and Mediterranean climates. The nuts closely resemble chestnuts, and they seem to yield almost as well despite no domestication efforts. Given their wide geographic potential, domestication and cultivation of Aesculus nuts for industrial starch seems worthy of consideration.